About the anodising process:

Aluminium, when exposed to the elements, gradually builds up a coating of aluminium oxide. Anodising is forced oxidisation of aluminium through electrolytic methods and achieves in minutes what nature takes years to accomplish.

This oxide becomes an integral part of aluminium and effectively retards future corrosion from the elements. An anodised surface is harder than the aluminium itself, this also helps to protect it.

Once anodised, any graphics or lettering added to the product are virtually permanent. Anodising can therefore be used when long life, abrasion resistance and multiple colours are required. Our studio offers a comprehensive design service and advice on this production process.

We recommend you contact us at an early stage in your project to discuss your requirements when we will be happy to offer advice on achieving the best results possible.

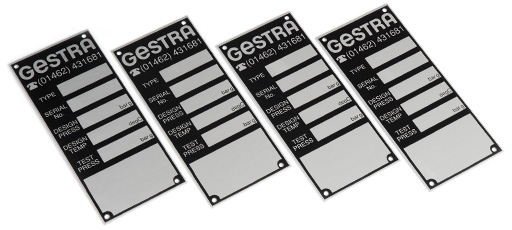

Anodised Name Plates

& Fascia Panels

Tough corrosion resistant anodised aluminium

with

high quality finish.

Anodised aluminium name plates and fascia panels. Anodised aluminium can be bead blasted, brushed, polished and printed, in fact finished to your exact specification.

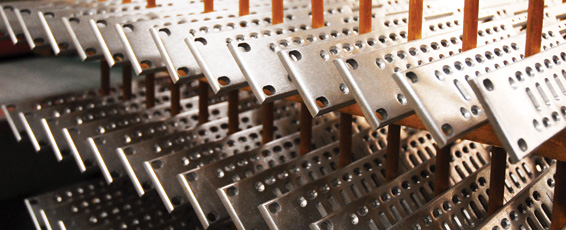

To your specification

Sheet metal work, fabrication, CNC machining, punching and laser cutting, all in-house.

Services

To the highest standards

Our ‘one-stop’ service covers the manufacture of chassis, enclosures, control panels, fascias, overlays, keypads, nameplates and labels. In-house finishing facilities include screen printing, stove enamelling, powder coating, RFI shielding, anodising and alocroming. We are ISO9001:2015 accredited. Valid Until: 21 February 2027.

Tel. 020 8543 8977

© Screencraft Precision Industrial Printers Limited. 2024 Website Design by Adelante