Manufacturing, engineering and printing under one roof.

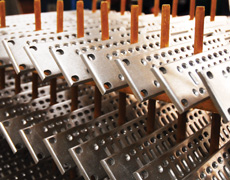

Established in 1972, we have expanded our facilities year on year and can now offer the total service for the manufacture of enclosures, and control panels. With our own in-house finishing which included plating, stove enamelling, powder coating and screen printing our service is the most comprehensive available.

Many of our clients already benefit from Screencraft’s expertise in not only supplying the enclosure, but also the chassis, printed fascia panels and internal parts finished to their specification.

Over many years Screencraft have manufactured numerous types of metal enclosures from small back boxes for wall switches, to 19” rack mount chassis and frames, as well as bench-top instrument cases. As an alternative to painting and printing, fascia panels can incorporate screen printed key pads in the form of polycarbonate overlays, with windows for displays and LEDs if required.

We work closely with electronic engineers, specifiers and designers to ensure that the finished product is manufactured to the highest possible quality.

A prototype service is available for new projects, a rapid turn round can be achieved as all manufacturing processes are carried out by Screencraft in-house.

Industries served include defence, communications, audio, broadcast, test and measurement, medical and security, to name but a few.

We recommend you contact us at an early stage in your project to discuss your requirements when we will be happy to offer advice on achieving the best results possible.

The complete

service

Manufacturing to the highest standards and tolerances.

Screencraft have been manufacturing, engineering and printing from our South West London premises for over 40 years. Recent additions to our facilities have included new Laser Profiling, CNC Punching and Sheet Metalworking machinery. Our product finishing department has recently been complimented by the addition of a wide belt graining system, automatic stud insertion and welding equipment.

Screencraft's quality Control is BS:EN ISO 9001:2015 accredited.

Certificate No: 2922

Reissued: 7 February 2024

Valid Until: 21 February 2027

To your specification

Sheet metal work, fabrication, CNC machining, punching and laser cutting, all in-house.

To the highest standards

Our ‘one-stop’ service covers the manufacture of chassis, enclosures, control panels, fascias, overlays, keypads, nameplates and labels. In-house finishing facilities include screen printing, stove enamelling, powder coating, RFI shielding, anodising and alocroming. We are ISO9001:2015 accredited. Valid Until: 21 February 2027.

Tel. 020 8543 8977