About our finishing processes:

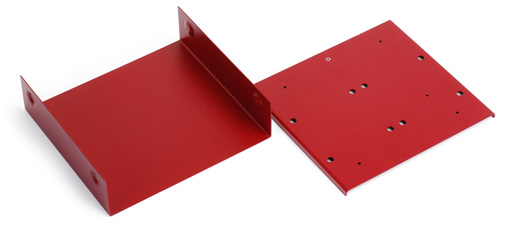

Screencraft offer a comprehensive finishing service for both metal and plastic components.

Our ongoing investment programme in our finishing department has enabled us to maintain a position at the forefront of developments within this area of our industry.

Most recent investments include 2 new temperature controlled ovens, a new powder coating unit and our own facilities to alocrom aluminium.

We recommend you contact us at an early stage in your project to discuss your requirements when we will be happy to offer advice on achieving the best results possible.

Product

Finishes

Wet Spray, Powder Coating & Stove Enamelling.

Stove Enamelling, Stoving Metallic, Stoving Hammer, Low Temperature Acrylic, Powder Coatings - Gloss and Textures. Plastilac Coatings, Nextel and Sensosoft Coating, RFI Shielding, High Temperature Epoxy Stove Enamelling and Gloss Clear Lacquer.

Services

To the highest standards

Our ‘one-stop’ service covers the manufacture of chassis, enclosures, control panels, fascias, overlays, keypads, nameplates and labels. In-house finishing facilities include screen printing, stove enamelling, powder coating, RFI shielding, anodising and alocroming. We are ISO9001:2015 accredited. Valid Until: 21 February 2027.

Tel. 020 8543 8977

© Screencraft Precision Industrial Printers Limited. 2024 Website Design by Adelante