About the prototype production process:

With the infinite variation of production methods offered by Screencraft, it is often possible to make a finalised prototype for client approval prior to the actual production run. Subject to the quantity and specific finish required of the final item it may be more cost effective to create a digital representation of the intended component, alternatively it may be possible to produce a final component as a prototype. This service is designed to eradicate costly production errors by identifying manufacturing issues prior to production.

We recommend you contact us at an early stage in your project to discuss your requirements when we will be happy to offer advice on achieving the best results possible.

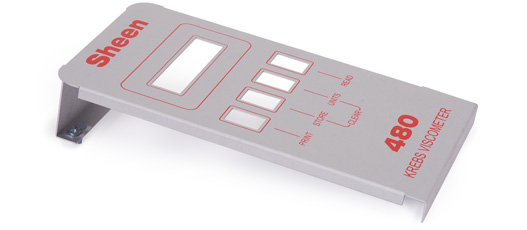

Prototype

Production

High quality, exact prototypes manufactured for your fascias and components.

Prototype Trims, Prototype fascias, Prototype instrument and control panels finished to perfection at our extensive in-house facilities, Screencraft are able to produce finished prototypes prior to the final production run.

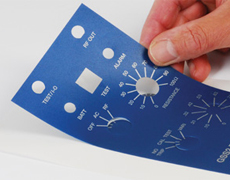

Polycarbonate Overlays

Highly durable and functional graphic overlays and fascias.

Services

To the highest standards

Our ‘one-stop’ service covers the manufacture of chassis, enclosures, control panels, fascias, overlays, keypads, nameplates and labels. In-house finishing facilities include screen printing, stove enamelling, powder coating, RFI shielding, anodising and alocroming. We are ISO9001:2015 accredited. Valid Until: 21 February 2027.

Domed Labels

Superior finish high quality self adhesive labels to your specification.

Tel. 020 8543 8977

© Screencraft Precision Industrial Printers Limited. 2024 Website Design by Adelante